Roll material selection and roll surface hardness

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 18:46

- Views:

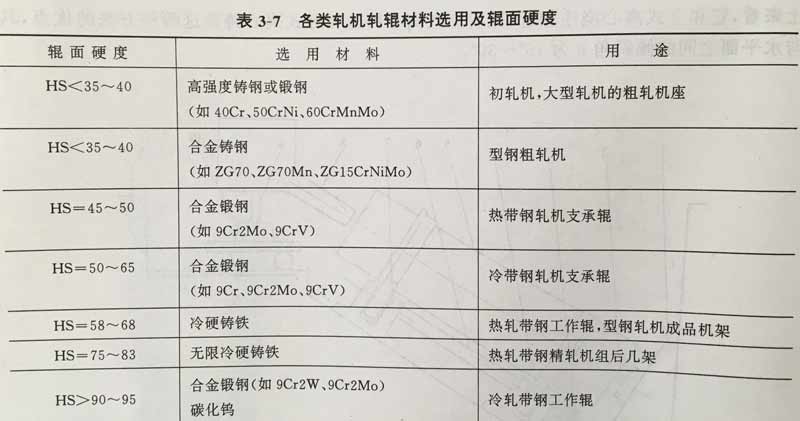

(Summary description)Theselectionofrollmaterialiscloselyrelatedtotheworkingcharacteristicsanddamageformsofroll. Therollerofthebloomingmillandprofilemillshouldhaveenoughstrengthandimpactload,andthehardnessoftherollersurfa

Roll material selection and roll surface hardness

(Summary description)Theselectionofrollmaterialiscloselyrelatedtotheworkingcharacteristicsanddamageformsofroll. Therollerofthebloomingmillandprofilemillshouldhaveenoughstrengthandimpactload,andthehardnessoftherollersurfa

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 18:46

- Views:

Scan the QR code to read on your phone

Domestic sales hotline:

025-56215336

Overseas:+86 18944068095

E-mail:hwb@njjxgear.com

Adress:No. 1, shuibao east road, nanqu district, lishui economic development zone, nanjing, jiangsu province

Nanjing jinxin transmission equipment co. LTD 苏ICP备11068727号-1