With the continuous improvement of rolling line speed, the rolling speed of finished frame has reached 14m/s. When rolling at such high speed, it is required to cut off lOOmm from the end and end of the steel. Because the head of steel, end is irregular, can cause pile steel accident, and steel end temperature is lower, can appear sometimes black head, if do not cut off, likely cause next machine frame overcurrent to cause bigger accident such as quick open trip. Therefore, the cutting head and the cutting end are set to facilitate the smooth running of the rolling line.

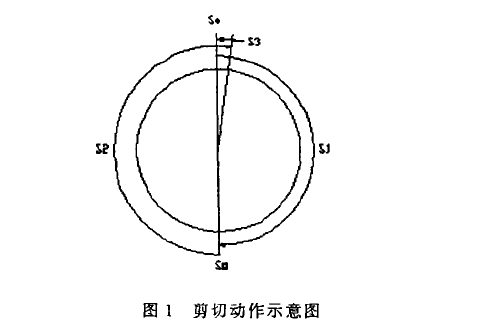

According to the technological requirements of rolling line, one action cycle of flying shear can be divided into four parts. See fig.1 attached.

When the rolled piece comes out of the heating furnace and enters the rough rolling close to the flying shear (or when the tail of the rolled piece is close to the flying shear), the flying shear blade starts and runs from the stop position Sa with constant acceleration a1. After traveling through S1, it reaches the given shear velocity V and has a certain steady speed process to cut the rolled piece.

After the shear is completed, when the shear blade reaches the braking position sb, it slows down with constant speed a2 to the climbing speed given Vl, and then reaches the original Sa through travel S2.

③ 剪刃正爬到原位Sa时,计数码盘的脉冲数清零,再进行反爬。

④ 经过行程S3,剪刃反爬到原位Sa时,给零速,且撤掉使能,剪刃就停在原位Sa处。至此完成一次剪切动作。