Profile of sizing reduction and pass system

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 19:12

- Views:

(Summary description)Reducing sizing machine is a new technology used in high speed wire mill in recent years. The unit is usually composed of 2 reducing machines, 2 sizing machines and 1 set of combined transmission tran

Profile of sizing reduction and pass system

(Summary description)Reducing sizing machine is a new technology used in high speed wire mill in recent years. The unit is usually composed of 2 reducing machines, 2 sizing machines and 1 set of combined transmission tran

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 19:12

- Views:

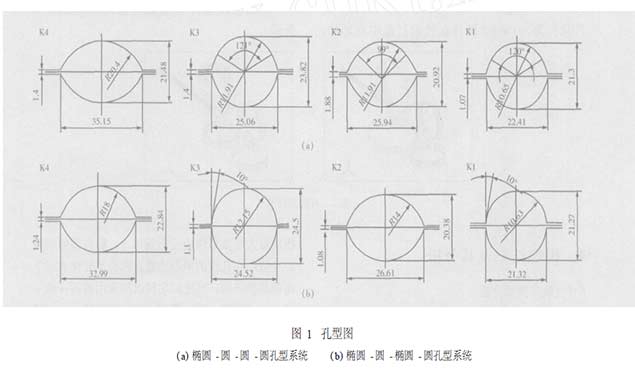

By means of finite element analysis software, this paper simulates the rolling process of two kinds of reduced-diameter pass systems, i.e., elliptic-circular-circle and elliptic-circular-elliptic-circle, and analyzes the deformation characteristics, the size of the rolled piece and the variation of the rolling pressure. The analysis can deepen the understanding of the groove system of the high-speed wire.High - speed wire sizing set followed by finishing mill group. The main function of the reducing sizing unit is as follows: 1) adopt low pressure rolling to ensure high accuracy of product size; 2) can realize free size rolling, which is conducive to the production of small batch and non-standard wire. 3) simplified the pass system and reduced the roll changing time; 4) low temperature control rolling process can be implemented to effectively improve the performance of wire. Therefore, the design of reducing bore should meet the above requirements. The reduced-size pass system used by domestic high speed wire mill is mostly imported from abroad together with the equipment. For example, if the specification of a factory is <21 mm round steel, an elliptic-circular-circular-circular pass system is adopted, as shown in fig.1a. For steel of <21 mm, an elliptic-circular-elliptic-circular pass system is adopted in another plant, as shown in FIG. 1b.

Scan the QR code to read on your phone

Domestic sales hotline:

025-56215336

Overseas:+86 18944068095

E-mail:hwb@njjxgear.com

Adress:No. 1, shuibao east road, nanqu district, lishui economic development zone, nanjing, jiangsu province

Nanjing jinxin transmission equipment co. LTD 苏ICP备11068727号-1