Eight pyramid coiler

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 19:15

- Views:

(Summary description)Thisyear,thecoldrollingmillisdevelopingtowardshighspeed,rewindingandautomation.Firstofall,toreducetherotaryinertiaofthecoiler,improvethestarting,speedregulation,brakingperformance,tendtoadoptthedirect

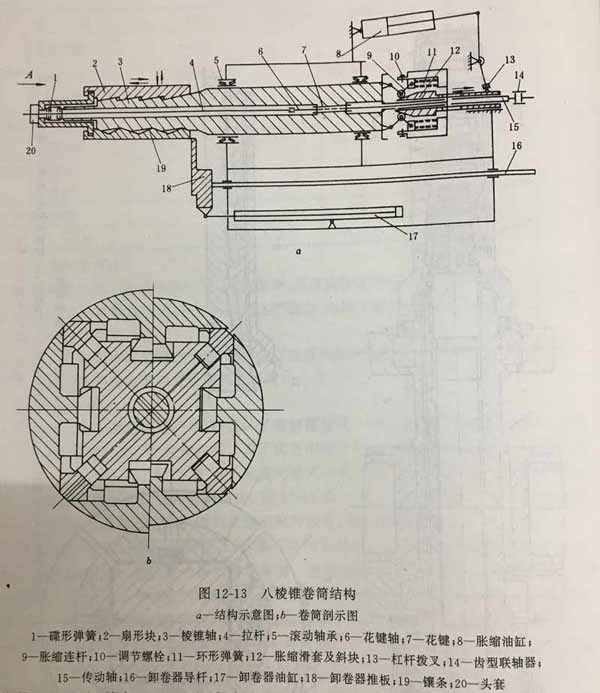

Eight pyramid coiler

(Summary description)Thisyear,thecoldrollingmillisdevelopingtowardshighspeed,rewindingandautomation.Firstofall,toreducetherotaryinertiaofthecoiler,improvethestarting,speedregulation,brakingperformance,tendtoadoptthedirect

- Categories:Company News

- Author:

- Origin:

- Time of issue:2018-11-18 19:15

- Views:

When reducing the diameter, the oil cylinder will pull out the inclined block through the lever fork, the expansion and contraction link will bend under the action of spring 1, and the compression and deformation energy of the fan-shaped block and spline shaft stored in spring 1 can be reset when the expansion diameter depends on spring 1. In order to improve the rigidity of the coiler, the coiler is provided with a movable support.

Scan the QR code to read on your phone

Domestic sales hotline:

025-56215336

Overseas:+86 18944068095

E-mail:hwb@njjxgear.com

Adress:No. 1, shuibao east road, nanqu district, lishui economic development zone, nanjing, jiangsu province

Nanjing jinxin transmission equipment co. LTD 苏ICP备11068727号-1