Our company rolling mill gear box structure features

- Categories:Company News

- Author:

- Origin:

- Time of issue:2017-05-22 11:52

- Views:

(Summary description)Gear box type: all the gear boxes of horizontal rolling mill are divided horizontally, and the transmission gears of all levels are arranged as far as possible at the dividing surface of the gear bo

Our company rolling mill gear box structure features

(Summary description)Gear box type: all the gear boxes of horizontal rolling mill are divided horizontally, and the transmission gears of all levels are arranged as far as possible at the dividing surface of the gear bo

- Categories:Company News

- Author:

- Origin:

- Time of issue:2017-05-22 11:52

- Views:

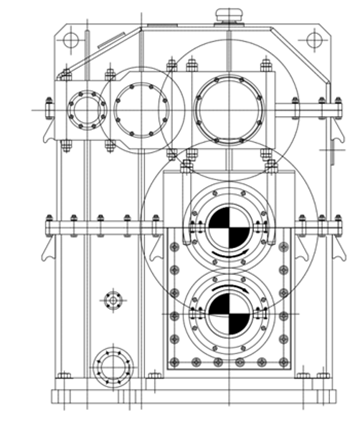

Gear box type: all the gear boxes of horizontal rolling mill are divided horizontally, and the transmission gears of all levels are arranged as far as possible at the dividing surface of the gear box. The gear meshing part of the reducer has observation holes, and the size of the observation holes is large enough. Transparent plexiglass should be used outside. The whole machine is equipped with divided floor. The horizontal gear boxes at 1H, 3H, 5H, 7H, 9H and 11H all adopt the vertical transfer form as shown in the figure below.

Lubricating mode: the lubricating of the reducer is forced lubrication by thin oil; Thin oil lubrication pipeline is arranged inside the box; Set the electrical contact flow signal meter + mechanical pressure gauge. The inlet and outlet tubing of gear box is connected by flange.

Scan the QR code to read on your phone

Domestic sales hotline:

025-56215336

Overseas:+86 18944068095

E-mail:hwb@njjxgear.com

Adress:No. 1, shuibao east road, nanqu district, lishui economic development zone, nanjing, jiangsu province

Nanjing jinxin transmission equipment co. LTD 苏ICP备11068727号-1